Interesting facts about the 747 - Boeing 747 | information center

Main menu

- Home Page

- Skyliner aviation

- All 747 by line#

- Cancelled orders

- 747s cashed or written off

- 747 History

- Boeing Identifiers

-

Production list

- 747-100 production

- 747-8 production

- Special versions

- Production by year

- Open questions

- Current status

- Facts and figures

- 747 maintenance

- Sources and credits

Interesting facts about the 747

The 747 was over 2.5 times larger than the Boeing 707, which was one of the most common commercial aircraft at the time.

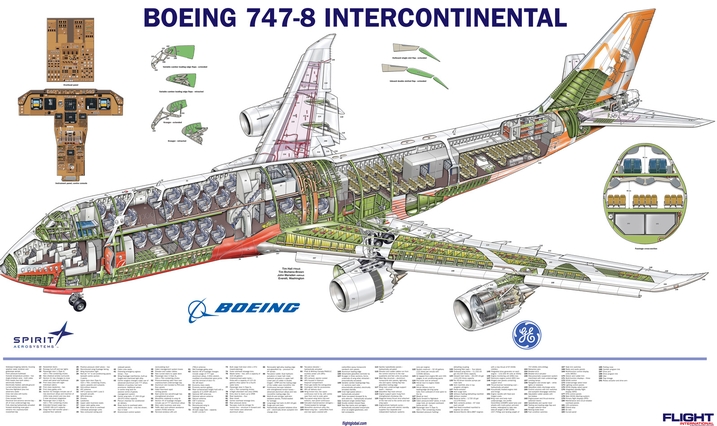

One of the main reasons the upper deck was designed was to allow the 747 to be easily converted into a cargo aircraft. At the time, designers thought supersonic transports would quickly make the 747 obsolete, and its role as a cargo aircraft was essential.

The original 747 design had the upper deck running the entire length of the fuselage, but because the plane couldn't safely be evacuated in the FAA mandated 90 seconds, the idea was thrown out.

Complex high-

lift devices were used so the 747 could operate out of existing airports. Leading edge slats and three- part fowler flaps increase the wing area by 21%, and increase lift by up to 90%

Boeing didn't have a facility large enough to build the 747, so they had to construct a new assembly plant in Everett, WA. The project timeline was so aggressive that the first 747 mockup was built before the building's roof was finished. The plant is still the largest building by volume in the world at over 13,000,000 cubic meters. It’s so large, it has its own weather systems inside, and clouds form inside the building.

There are 365 switches, dials, and lights in the incredibly confusing cockpit (dash 400). One for every day of the year. Apparently this is down from 971 (in Classic versions).

There are 14 stairs to the upper deck.

That upper deck alone has the same square footage as a 737.

Early models of the 747 had a high-

speed flutter problem in the wings. Engineers solved the problem by placing depleted uranium counterweights in the outboard engine nacelles.

The project was so expensive that Boeing struggled to get the loans to complete the project. Boeing had over 2 billion USD in debt -

the most for any company at the time.

The 747 has a wing sweep of 37.5 degrees -

more than any other commercial aircraft in the world. In transonic flight, a swept wing allows a higher Critical Mach Number than a straight wing of similar Chord and Camber. This results in the principal advantage of wing sweep which is to delay the onset of wave drag.A swept wing is optimised for high speed flight. Low speed handling characteristics and lift generation are improved by the addition of High Lift Devices such as Slats and Flaps.

The Evergreen 747 Supertanker, a modified 742-

200, is the largest aerial firefighting aircraft in the world. It can hold up to 20,000 gallons of firefighting chemicals.

NASA chose the 747 to haul its space shuttles over the C-

5 Galaxy for two reasons. 1) The low wing design made it easy to mount the shuttle, and 2) NASA could own the 747s, while they couldn't own an Air Force C- 5.

At the Boeing training school, pilots were trained for taxiing the giant with the help of a piece of equipment called the ‘Waddell's Wagon’—a simulated flight deck perched on three-

story- high stilts on a moving truck. The pilots communicated with the truck driver via radio to learn how to manoeuvre from the unprecedented height!

Parts

A 747-

400 has six million parts, half of which are fasteners.

A 747-

400 has 171 miles (274 km) of wiring and 5 miles (8 km) of tubing.

A 747-

400 consists of 147,000 pounds (66,150 kg) of high- strength aluminum.

The 747-

400 has 16 main landing gear tires and two nose landing gear tires.

The 747-

400 tail height is 63 feet 8 inches (19.4 m), equivalent to a six- ey building.stor

Wings

The 747-

400 wing weighs 95,000 pounds (43,090 kg), more than 30 times the weight of the first Boeing airplane, the 1916 B&W.

The 747-

400 wing measures 5,600 square feet (524.9 m 2 ), an area large enough to hold 45 medium- sized automobiles.

Four World War I vintage JN4-

D "Jenny" airplanes could be lined up on each of the Boeing 747 wings.

How much weight does an additional 6-

foot (1.8- m) wingtip extension and winglet add to the 747- 400 wing? None! A weight savings of approximately 5,000 pounds (2,270 kg) was achieved in the wing by using new aluminum alloys, which offset the weight increase of the wing tip extension and winglet

Engineering and Testing

Seventy-

five thousand engineering drawings were used to produce the first 747.

The first 747 completed more than 15,000 hours of wind-

tunnel testing.

The original 747 flight test program, which led to the airplane's certification for commercial service in December 1969, used five airplanes, lasted 10 months and required more than 1,500 hours of flying.

Flight

The 747 fleet has logged more than 42 billion nautical miles (77.8 billion kilometers), equivalent to 101,500 trips from the Earth to the moon and back.

The 747 fleet has flown 3.5 billion people -

the equivalent of more than half of the world's population.

The 747-

400ER range is approximately 7,713 nautical miles (14,297 km).

A 747-

400 typically takes off at 180 mph (290 km/h), cruises at 565 mph (910 km/h) and lands at 160 mph (260 km/h) .

For a typical international flight, one 747 operator uses about 5.5 tons (5,000 kg) of food supplies and more than 50,000 in-

flight service items.

Fuel

The 747-

400ER can carry more than 63,500 gallons of fuel (240,370 L), making it possible to fly extremely long routes, such as Los Angeles to Melbourne, Australia.

A 747-

400 that flies 3,500 statute miles (5,630 km) and carries 126,000 pounds (56,700 kg) of fuel will consume an average of five gallons (19 L) per mile.

The 747-

400 carries 3,300 gallons (12,490 L) of fuel in the horizontal (tail) stabilizer, allowing it to fly an additional 350 nautical miles.

Engines

Engine thrust has grown from 43,500 pounds (19,730 kg) per engine on the early 747s to as much as 63,300 pounds (28,710 kg) on the current model.

The diameter of the 747 engine cowling is 8 feet 6 inches (2.6 m).

Interior

The award-

winning Boeing Signature Interior is available on both the 747- 400 and 747- 400ER.

At 31,285 cubic feet (876 cubic meters), the 747-

400 has the largest passenger interior volume of any commercial airliner, which is equivalent to more than three houses each measuring 1,500 square feet (135 square meters).

The 747-

400 has a redesigned "flexible" cabin interior that allows airlines to rearrange seats and class configuration overnight (in eight hours). They also permit 48- hour conversion times for changes in galley and lavatory locations.

Airline cargo handlers use the 747-

400's lower- lobe cargo handling system to load or unload more than 65,000 pounds (30,000 kg) of cargo - the equivalent of 625 pieces of luggage combined with 20 tons of revenue freight - in less than 15 minutes.

The Wright Brothers' first flight at Kitty Hawk, N.C., could have been performed within the 150-

foot (45- m) economy section of a 747- 400.

There are 365 lights, gauges and switches in the new-

technology 747- 400 flight deck, reduced from 971 on earlier 747 models.

About the missing H.F. wingtip antennas here is your answer:

Boeing in the late '80's started to offer an option on the 747's where the old style wing tip H.F antenna could be placed on the leading edge of the vertical stabilizer, hence the lack of H.F wing tip antennas on many Classic 747s and all of the dash 400s.

The Integral Antenna Installation deactivates the existing left and right wing probe Antennas and installs a composite Dorsal Fin Notch Antenna with the HF Antenna element mounted internally. Notch Antenna program will take the existing HF system into the 21st century by improving HF receive and transmit to help meet the requirements for HF Datalink.

The installation of the HF Antenna and improved location of the antenna tuning and feed components results in a dramatic improvement of the radiation pattern achieved. The upgrade program includes the installation of a notch antenna located in the dorsal fin, and the installation of new HF antenna couplers inside the pressure vessel, below the new antenna. Both wing tip couplers are removed as part of the installation. The Dorsal Fin Notch Antenna program is a retrofit program that has been designed to be installed without additional down time during routine aircraft maintenance. The design of the HF dorsal fin notch antenna reduces the impact of lightning strikes on the aircraft. Integrating the antenna into the existing dorsal fin of the aircraft maintains the structural integrity of the fuselage. Design of the kit is focused on rapid installation and allows it to be accomplished in about 175 man-